Where Deep Learning Meets Real-World Precision

Cutting-Edge Computer Vision AI Technology

Intelligent Image Analysis

Our proprietary computer vision algorithms have been trained on millions of manufacturing images to identify defects with unprecedented accuracy and speed.

- High-resolution multiangle imaging

- Real-time processing capabilities

- Adapts to different lighting conditions

- Detects microscopic defects human inspectors may miss

- Stable performance in industrial environments

Advanced Neural Networks

Deep Learning Architecture

Our system uses a custom-developed neural network architecture specifically designed for manufacturing defect detection, combining supervised and unsupervised learning approaches.

- Trained on industry-specific datasets

- Continuously improving accuracy over time

- Learns from new examples with minimal training

- Identifies patterns invisible to traditional computer vision

- Proprietary anomaly detection algorithms

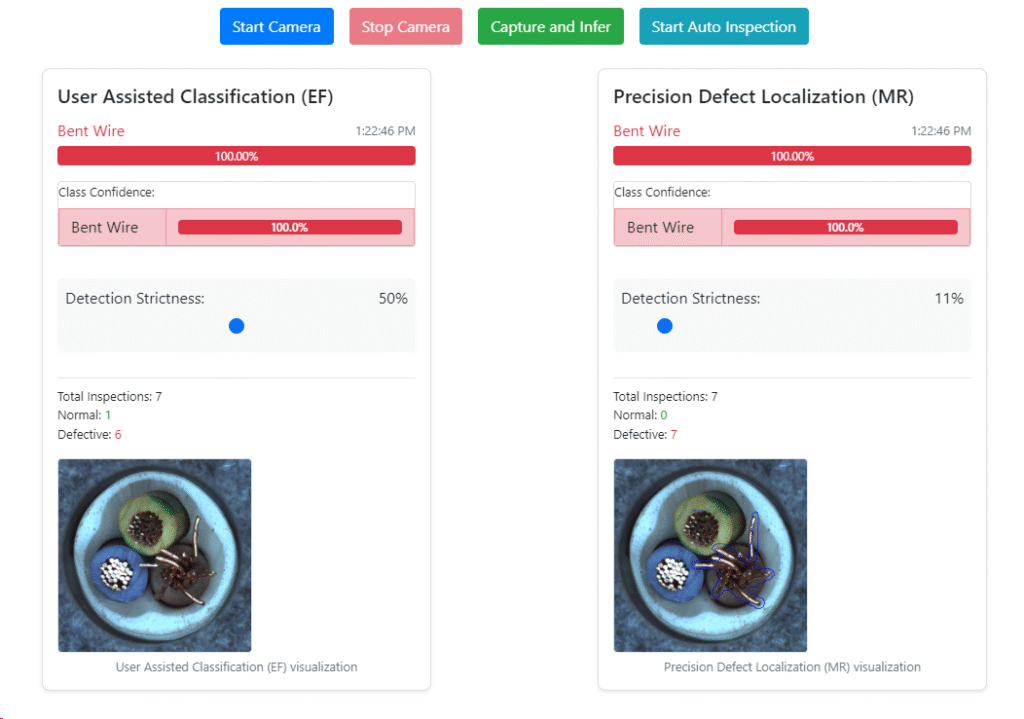

Multi-Model Inference Engine

Multiple AI models run simultaneously, each specialized for different types of defects or product variations. This flexible approach ensures optimal detection across diverse manufacturing processes.

- Switch between models with a single click

- Compare detection results across different models

- Fine-tune sensitivity for each model independently

- Application specific model training

Advancing inspection. Empowering precision.

At Synthomatic, we’re advancing AI and machine vision to solve manufacturing’s toughest quality challenges - empowering you to deliver flawless parts with confidence

Advanced Technological Features

Our AI-powered quality control system delivers a comprehensive solution engineered specifically for manufacturing environments.

Application Specific Models

Even when sample parts or defect images are limited, models are fine-tuned for each customer application to ensure the highest level of confidence and detection capability.

Process Improvement Analytics

Beyond detection, our system delivers actionable insights on defect patterns and root causes, enabling targeted process improvements that reduce recurrence and boost overall quality.

Multi-Defect Classification

Simultaneously identifies multiple types of defects in a single pass, categorizing each by type, severity, and recommended action.

Adaptive Learning Capability

EyeQ360 continuously learns from new data, improving defect detection accuracy over time and adapting to manufacturing process changes.

Customizable Parameters

Adjustable sensitivity and detection thresholds to balance between detection rate and false positives based on your specific requirements.

Secure Data Management

Enterprise-grade security for your production data with optional on-premises deployment for sensitive manufacturing processes.

Ready To See How Our Technology Improves Your Quality?

Contact our team today to schedule a personalized demonstration of our AI quality control system.