Advancing the Future of Quality with AI-Powered Inspection

At Synthomatic AI Solutions, we take a customer-intimate approach to business. We don’t simply sell hardware, we deliver comprehensive manufacturing solutions tailored to your specific needs. Our products are seamlessly integrated into your processes, ensuring a smooth installation and immediate, effective performance.

Desktop to Fully Automated. Advanced AI Built to Evolve.

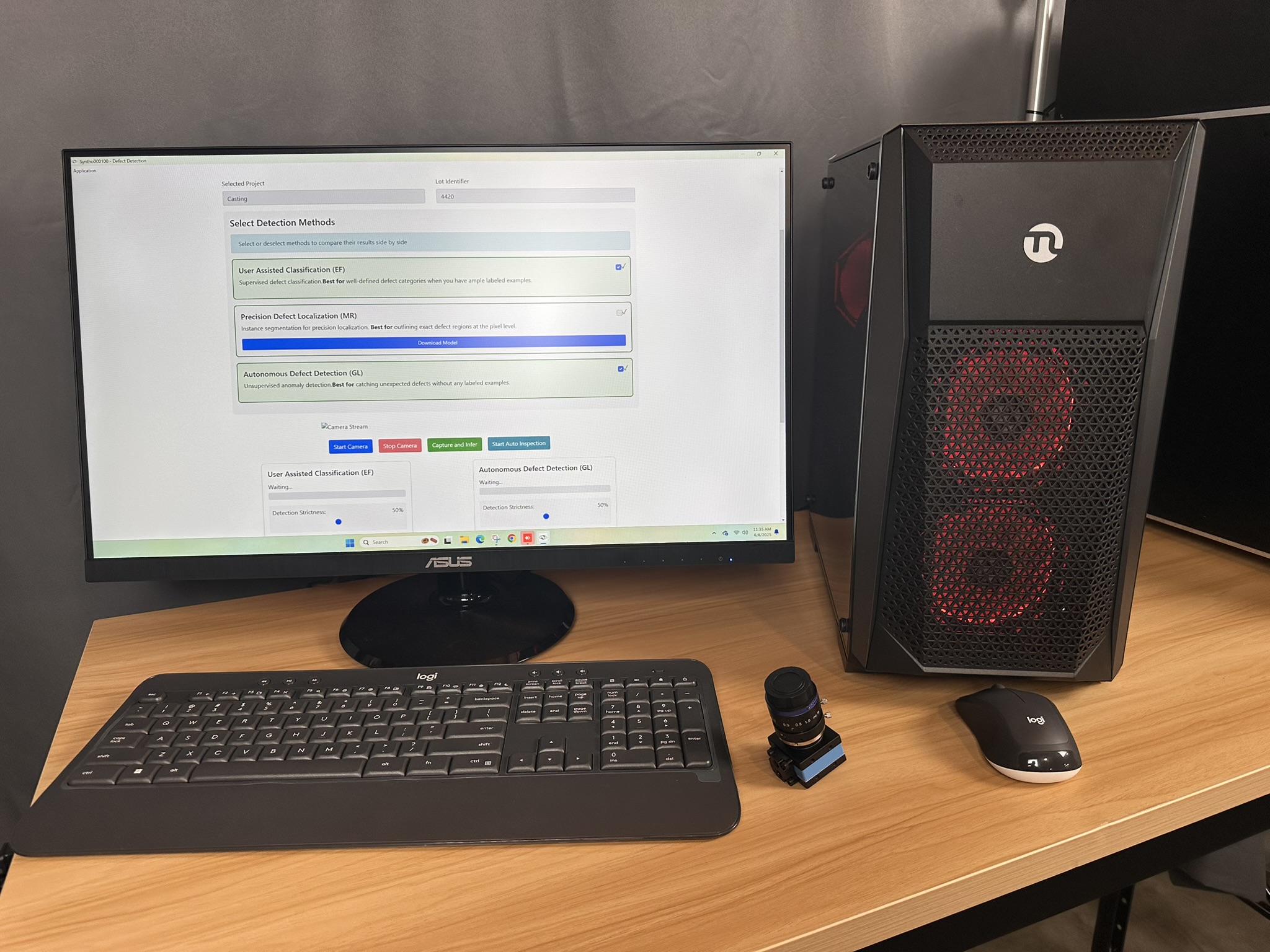

S300: Built-to-Integrate

This integration-ready kit includes everything needed to add advanced AI inspection to your existing equipment: a powerful computer, EyeQ360 software, camera, and lighting.

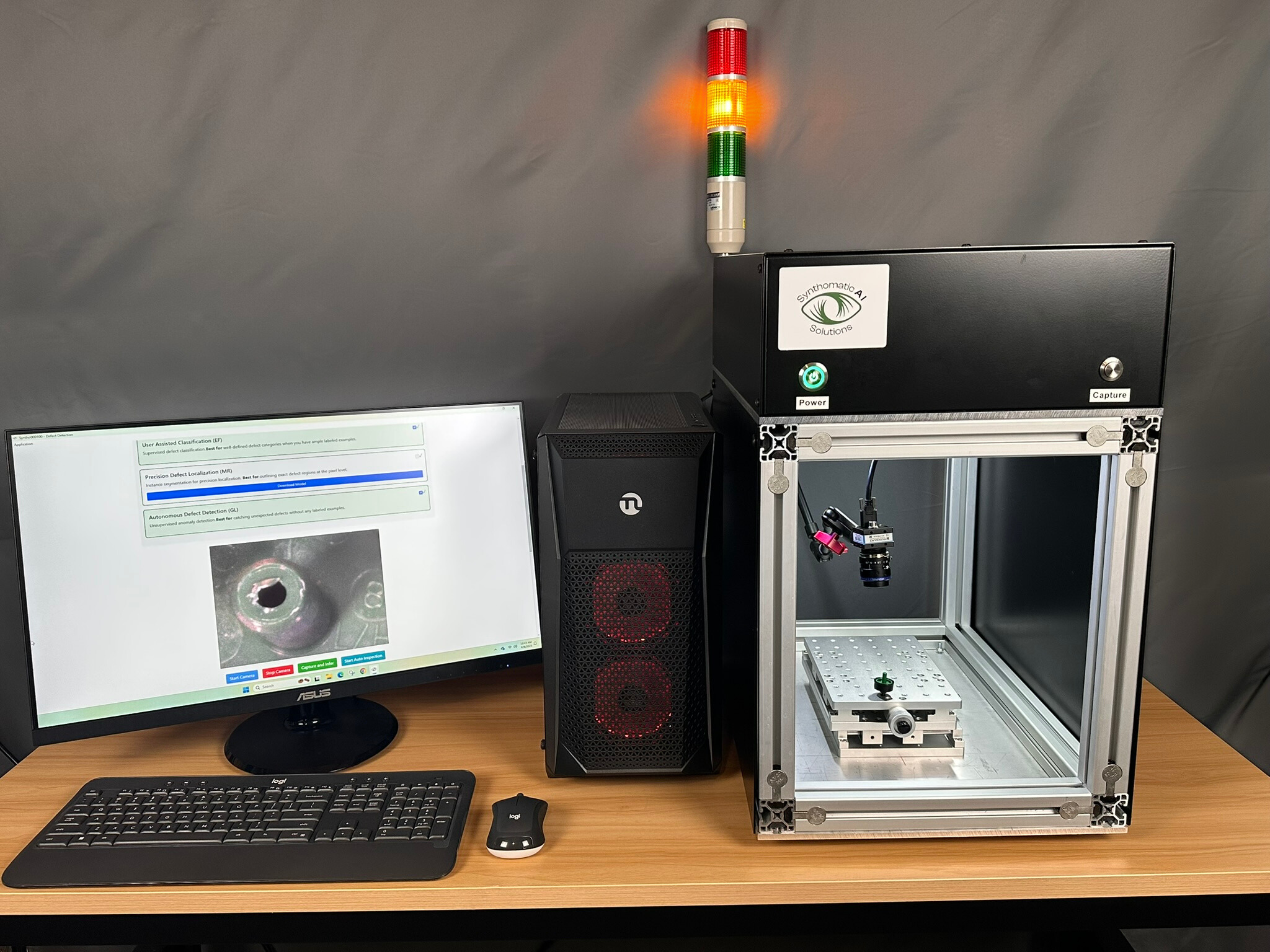

S500: All-in-One AI Inspection

This standalone system is fully enclosed and factory ready. It includes a powerful computer, EyeQ360, camera and lighting, part fixturing, operator interface panel and signal tower, and built-in PLC and I/O.

S700: Fully Automated

This turnkey system delivers end-to-end inspection automation with all the features of the S300 but with added automation for material handling. Ideal for high-throughput environments.

EyeQ360: AI-Powered Vision. Beyond Human Limits.

EyeQ360 Makes AI Inspection Effortless

In just three simple steps, you can train, select your inspection method, and start identifying defects with precision.

EyeQ360 also provides intuitive heatmaps, detailed analytics, and performance reports that help you boost productivity, yield, and profitability.

Inspection has never been this easy – 1, 2, 3

Multiple Detection Modes, Traceability, & Analytics

EyeQ360 delivers powerful defect detection with minimal training data. Whether you have no defect examples, just a few, or a large dataset, EyeQ360 intelligently selects from multiple model types to match your situation.

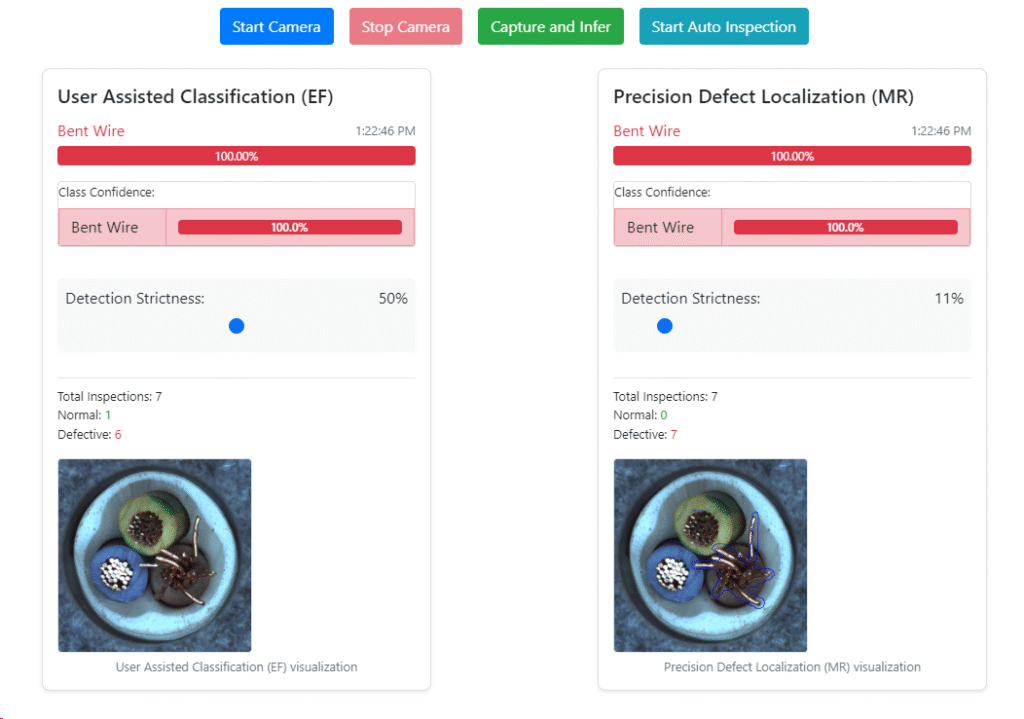

Multiple Detection Modes

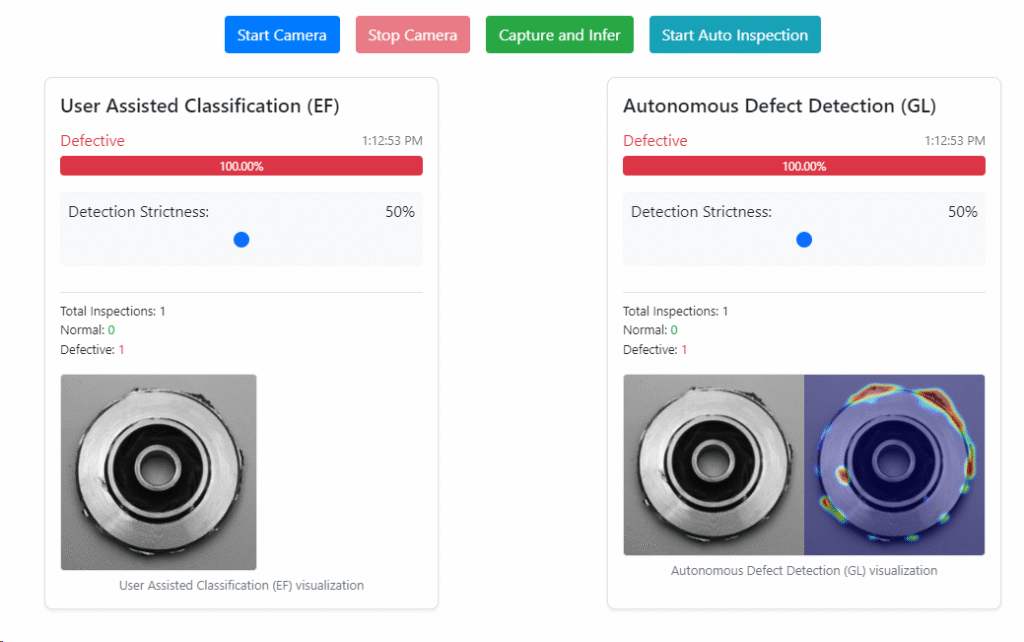

1. User-Assisted Detection

Ideal for scenarios with well-defined defect types, this mode combines human expertise with AI support. Users guide the system by labeling or confirming known defects, allowing EyeQ360 to detect them rapidly and consistently across inspections.

2. Precision Defect Localization

Designed for pinpoint accuracy, this mode excels at identifying specific defect locations or types. Whether it’s a micro-crack, edge burr, or surface contamination, EyeQ360 highlights the exact spot and nature of the defect for fast, focused action.

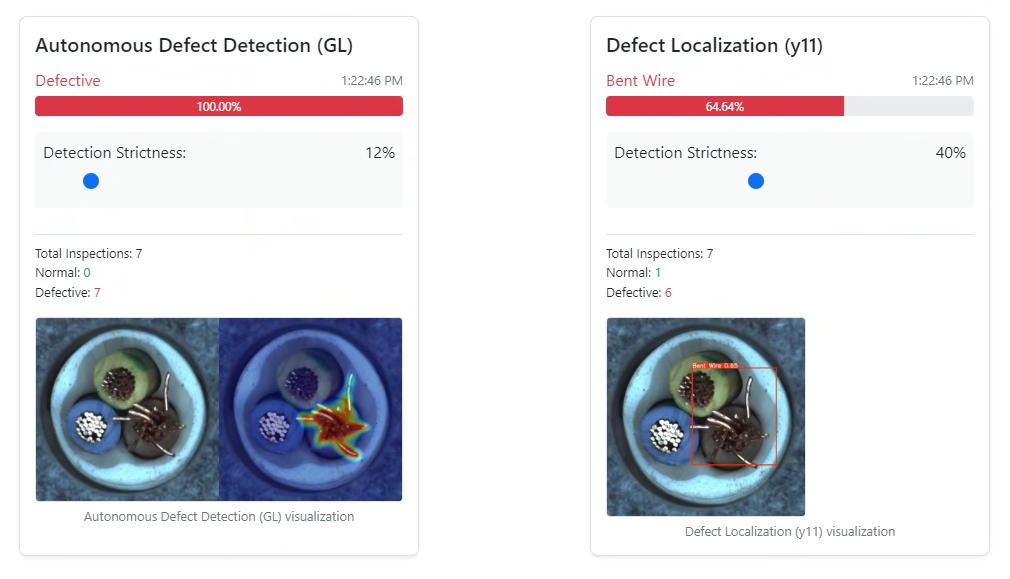

3. Autonomous Defect Detection

For unknown or unexpected defects, this fully automated mode leverages AI to detect anomalies without prior examples. It’s ideal for catching early process deviations, rare flaws, or edge cases that human inspectors might overlook.

EyeQ360 is also capable of classifying the defect type, giving the user deeper insight into quality trends.

Detection Results & Traceability

The Detection Results Page empowers users to evaluate and compare all three AI detection modes—User-Assisted, Precision Defect Localization, and Autonomous Detection—in one streamlined view. Each mode’s performance is clearly reported, helping users select the most effective approach for their application.

- Total Inferences Completed, with timestamps for full traceability

- Defects Identified, categorized by detection method and severity

- Image-Based Overlays, showing the precise defect locations on each part

- Audit-Ready Reporting, ensuring inspection results are logged, exportable, and compliant with quality standards

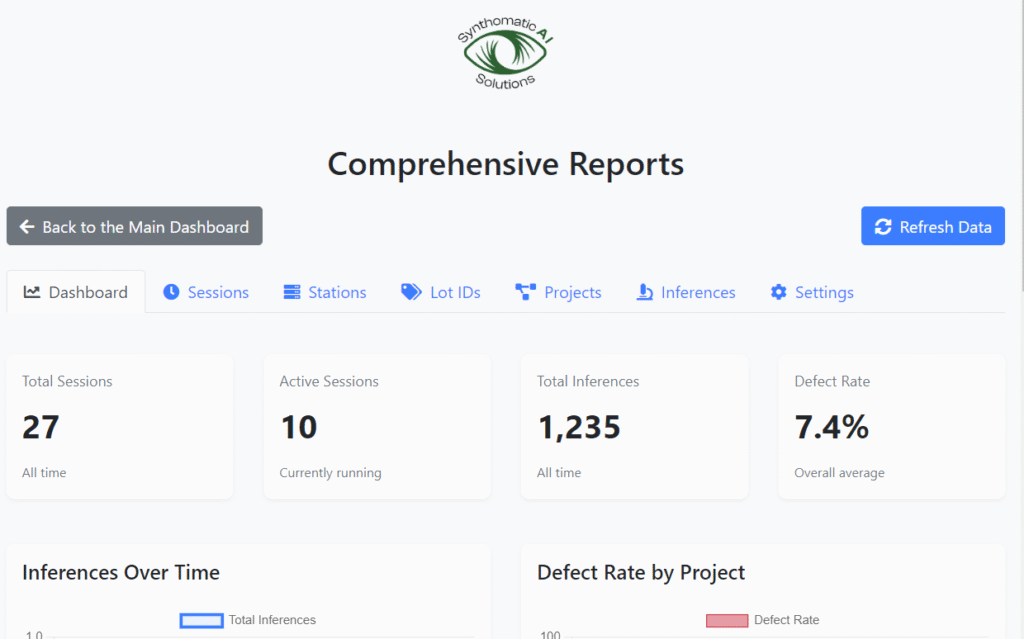

Keep an Eye on Factory-Wide Performance

Comprehensive reporting provides a historical view of inspection performance across the entire factory. Users can monitor total inferences completed and defects detected over time, aggregated across all stations or filtered by project, part type, or lot identification number.

Key features include:

- Factory-Wide Analytics: View performance across all inspection stations

- Custom Filters: Break down results by part type, lot number, or project

- Defect Trends Over Time: Identify recurring issues, process drift, or quality improvements

Cost & ROI Insights: Track EyeQ360’s impact on defect rates, rework reduction, and overall return on investment

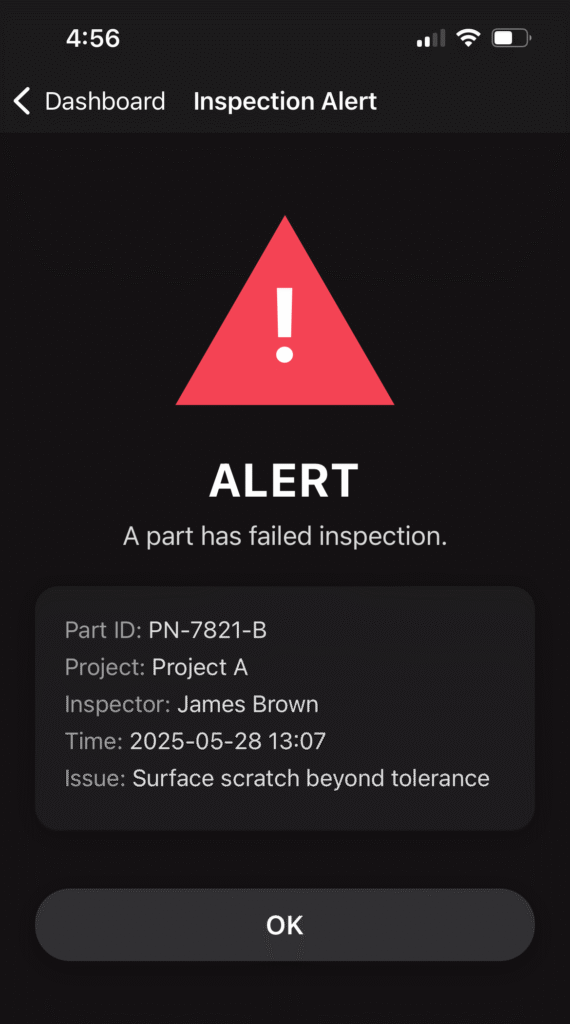

EyeQ360 Mobile App: Instant Insights. Anywhere You Go.

Stay connected to your factory floor – anytime, anywhere. The EyeQ360 mobile app delivers real-time performance metrics and sends instant alerts when defects are detected. Whether you’re on-site or off, you’ll always know how your inspection systems are performing and when action is needed.

Parts Inspected

Yield Achieved

Defects Identified

Engineered for the Most Demanding Industries

Aerospace & Defense

Critical components demand flawless quality and traceability. EyeQ360 helps meet strict regulatory and safety standards with high-precision AI inspection.

Medical Devices

Where human safety depends on perfection, EyeQ360 delivers consistent, validated defect detection that supports compliance and FDA readiness.

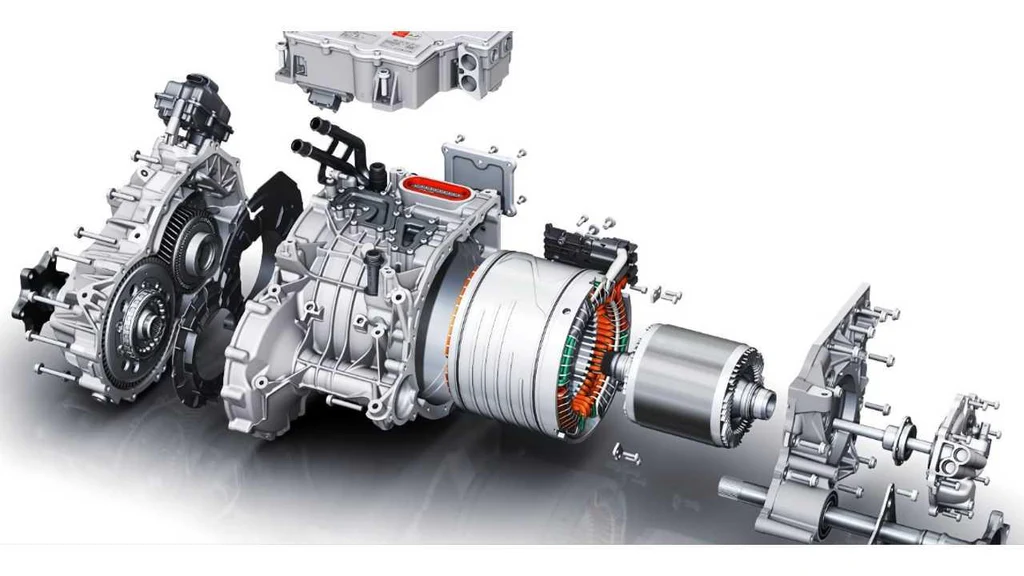

Automotive & Mobility

From powertrain to electronics, EyeQ360 helps maintain tight tolerances and high throughput in demanding production environments.

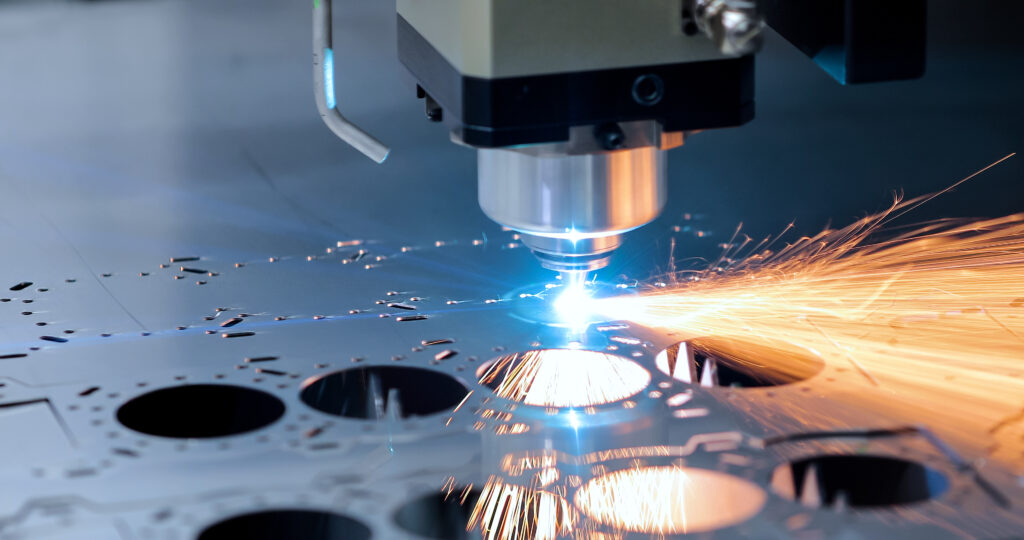

Precision Machining & CNC

Machine shops producing complex parts benefit from automated inspection that catches defects early and ensures part conformity.

Precision Inspection Across All Applications

Welding

Poor Coverage, Missing

Undercut

Cracks

Spatter

Molding

Warping

Shapes

Flashing

Burn Marks

Soldering

Cold Joints

Insufficient

Bridging

Webbing/Splashes

Assembly

Missing

Misalignment

Debris, FOD

Damaged Components

Machining

Surface Finish

Defects

Missing Features

Wiring

Polarity/Orientation

Missing Wires

Routing

Cutting/Punching

Edge Definition/Burrs

Surface Finish

Incomplete Cuts

Labeling

Location

Orientation

Missing

Ready To See How Our Technology Improves Your Quality?

Contact our team today to schedule a personalized demonstration of our AI quality control system.